News

EXPERTISE DRIVES SUCCESS December 2, 2021

BARNES buildings & management group, inc. brings quality, strength to design-build projects

Metal building systems are known for value construction. Those built by BARNES buildings & management group, inc. (BARNES buildings) are best known for their quality from start to finish.

Since 1996, the company has brought industry experience, design, value engineering and professional installation to each design-build metal structure it creates. “The advantage we have is that we know the manufacturing side,” says Marty Barnes, CEO of this Weymouth, Massachusetts-based company. “My early years as a detailer gave me a good idea of how the companies operate and how designs are done. Because of this, we can easily communicate with manufacturers and that ensures accuracy and efficiency for all our projects,”

The company also has the advantage of being a single source for customers. “Since 2006, we have owned and operated a structural steel and iron fabrication facility in Hanover, Massachusetts,” says Tony Barnes, President. “This makes us different because we are a full-service steel provider able to do the complete package, including structural steel, rails, stairs or a small addition to an existing building. The management part of our name refers to our ability to manage the entire project for customers with our suppliers, our own fabrication and our trained and equipped crews.”

The company also has the advantage of being a single source for customers. “Since 2006, we have owned and operated a structural steel and iron fabrication facility in Hanover, Massachusetts,” says Tony Barnes, President. “This makes us different because we are a full-service steel provider able to do the complete package, including structural steel, rails, stairs or a small addition to an existing building. The management part of our name refers to our ability to manage the entire project for customers with our suppliers, our own fabrication and our trained and equipped crews.”

As CEO, Marty is involved in estimating and sales and Tony runs the day-to-day operations that include planning and execution with field personnel and weekly jobsite visits.

Building with Experience

BARNES buildings serves general contractors, developers and building owners in New England—primarily in Massachusetts, Rhode Island, Southern New Hampshire and Maine. The company has also worked in Connecticut, New Jersey, New York and Chicago, where, in this last instance, it completed a job for an existing customer. Its crews use the engineered metal systems that BARNES buildings provides to construct the core and shell of the steel buildings, along with supplying and installing the architectural metal roof and wall panel systems.

For all its customers, the company offers a wealth of experience. “With my background and our five senior construction managers, we have 137 years of experience in steel building and commercial construction,” Marty says. “I’ve been in steel building for 47 years. You don’t stay in this business unless you love it.” After earning a degree in architectural engineering in 1973 from Wentworth Institute of Technology, Boston, he worked as a structural detailer for a metal building manufacturer. Later, he was the New England district sales manager for Metallic Building Systems before starting BARNES buildings.

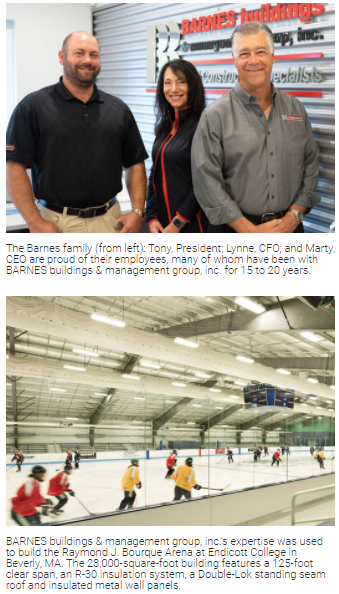

The Barnes family shares Marty’s enthusiasm for the industry. His wife, Lynne, is CFO, and after 15 years as a senior banking executive, she joined the team in 2009. She has been instrumental in directing the firm’s accounting and financial functions along with being the primary contact for all contracts, insurance and human resources. Their son, Tony, worked his way up to become President of the company. Tony worked at BARNES buildings part-time when he was in high school and while studying at Wentworth. He began as a laborer, progressed to journeyman and became a foreman when he was 24 years old. After BARNES buildings opened its steel fabrication business, Tony became its General Manager in 2007. He was in charge of all sales and operations for eight to 10 years while still working on the metal buildings side of the business. In 2016, he became BARNES buildings’ Vice President of Operations, in charge of all field aspects for the buildings side while continuing to manage the fabrication group. He became President of the company in 2020.

Designing for Results

“Our competitive advantage is the amount of experience we bring to the table, including value engineering when needed,” Tony says. “We can complete complex metal building projects, and we keep learning, striving to be at the next level above our competitors.”

Their efforts have earned the 2019 and 2020 Building of the Year award from Metallic Building Systems and two 2021 project awards from the Metal Building Contractors & Erectors Association (MBCEA). These include: an Award of Merit in the Manufacturing and Warehouse category for the Millstone Medical structure in Fall River, Massachusetts, a 60,000-square-foot medical device packaging facility; and an Award of Excellence for its work on the 45,000-square-foot SRC Medical warehouse and office facility in Hanover, Massachusetts. The company was also just named the Top Volume Builder in the country by Metallic Building Systems, which is quite an honor considering there are almost 400 builders nationwide.

BARNES buildings has also helped other types of companies build more efficiently. “Two minor league baseball stadium projects started out as conventionally designed and were way over budget,” Marty says. “We offered an engineered building systems solution and saved them enough money to move both projects forward sooner. One of these stadiums, the Northeast Delta Dental Stadium is home to the New Hampshire Fisher Cats and is also used by the Toronto Blue Jays. That was 20 years ago. Recently, we did the same for a project with Dellbrook/JKS, a general contractor in Quincy. The Alma del Mar Charter Schools’ municipally funded school in New Bedford was originally going to use conventional construction. We offered an engineered building system solution and saved considerable money so they also were able to move forward sooner.”

The company’s products and expertise are a good fit for many types of projects, including commercial, industrial, distribution, institutional and recreational structures. BARNES buildings’ crews have built more than two dozen sports arenas and facilities that are both multisport and multiuse. Many are notable, such as the Campanelli Stadium, Brockton, Massachusetts, home field of the Brockton Rox baseball team; a recreation center for the Boston Sports Institute; in Wellesley and the Canton Ice House in Canton. Its work also includes gymnasiums for schools in Massachusetts, including Pingree School, a high school in South Hamilton; Xaverian Brothers High School in Westwood; St. John’s Prep School for grades 6 through 12 in Danvers; and Endicott College, in Beverly. “We are so fortunate to have a wealth of talent to bring to the table for our customers,” Tony says. This includes Tim Allison, Executive Vice President, who has been with the company since its inception; Anthony Poliatti, Vice President of Project Management; and Chris Gunter, Director of Field Production. BARNES buildings’ engineered steel building systems also are ideal for the multiple cannabis facilities that the company has built in Massachusetts. The company will shortly break ground on a new project in Connecticut.

Its clients include general contractors, developers, building owners and construction managers, but BARNES buildings’ leaders find the company has the most success working with architects in the design phase where they can offer their expertise when the ideas and solutions begin.

“This is a solutions-driven industry and we have some great ideas for alternative methods of construction that will save our customers money, particularly on designs,” Marty says.

“We offer products for structural framing, cladding and roofing that provide many benefits to end users. In the end, it translates to lower prices with higher quality than traditional construction,” Marty continues. “We give you a good bang for your buck because we always try to save money for our clients and give them a great value. We try to do this in the design stage to avoid multiple redesigns. Our track record doing this is excellent.”

Keeping a good relationship with customers is the key to our success. I believe it’s because we are honest, good people to work with, and we are real team players at all times.”Marty Barnes, CEO, BARNES buildings & management group, inc

Selecting and Training Long-Term Winners

BARNES buildings employs 30 full-time people. When more field staff is needed, it uses a trained labor pool with whom Marty has a longstanding relationship.

“There are always BARNES buildings employees on every job,” Tony says. “Most competitors will subcontract the erection part of the project, but we are a single-source provider that furnishes and installs the buildings, including the core and the shell. That means we deal directly with any and all issues. With our competitors, any issue can easily become a finger-pointing exercise of who’s responsible.”

All employees are trained by the company, and many have worked at BARNES buildings for 15 to 20 years. “We look for people who want a career and not just a job. We’re fortunate to have excellent people working here,” Tony says. “This is an opportunity-type of business where many laborers have become foremen and managers. It’s also a place to meet people. A lot of field employees have become good friends outside work,” he adds.

The company has a reward program for current employees who find new team members. “Most of our employees are referrals from existing staff. We try to find the right people to begin with, so all new hires have a probationary period. This is a physical job where workers are outside in the elements. It also takes a certain personality. During the probationary period we discover whether the new employee and BARNES are a good fit for each other,” Tony says.

All new team members must also go through safety training. “A pre-employment requirement is an OSHA 10 certification. Before the new employee goes out on a job site, they must complete an MBCEA training series. From there, they have a safety orientation with Tim, our Executive Vice President, who is also our safety director. Our industry is considered higher risk, so there is a laundry list of safety training protocols our field staff need to follow. We have a culture of safety here. Our motto is ‘safety, quality, production.’ In the field, employees jointly police their own safety, quality, reliability and production,” Tony explains.

Mutual respect is another key element within the company. “All of our team members are very dedicated people who take their job personally,” Marty adds. “We pay them well and treat them well. I’ve always believed in treating people the way I want to be treated.” The company also hosts various summer outings and year-end events.

Encouraging New Ideas

The best way to find solutions is to open the door for ideas. That’s what happens at BARNES buildings. “I love new ideas and believe there are no bad ideas or stupid questions. If someone has a great idea, we’ll run with it,” Tony says. “We’ve been at this a long time, but the learning never stops. A coach once told me if you’re not getting better, you’re actually getting worse, because someone else is learning and getting better. After going to seminars or trade shows we’ll share what we saw or learned. Plus, every project is a new adventure, so we like to get ideas from foremen and employees and let them have buy-in on the details. They work more efficiently and better when they’re part of the process.”

Most of the company’s business is from return customers. “Keeping a good relationship with customers is the key to our success,” Marty says. “I believe it’s because we are honest, good people to work with, and we are real team players at all times. We stay on target, budget and timeline to honor our commitment. Even with supply-chain issues for steel, we do all that we can to fulfill our promise. Plus, when we build something, we’ll service it. If we make a mistake, we step up and make it right.”

Supporting Community Activities, Special Causes

Marty, Lynne and Tony are involved in community outreach. The company sponsors teams in baseball, soccer and football and supports The Arc of the South Shore, an organization that empowers disabled individuals.

Their largest outreach is with the Boston Chapter of the SEAL Legacy Foundation. They sponsor and work on the committee that helps to organize the local events. The Foundation has a program with Home Base, designed primarily for PTSD healing for veteran SEALs. It also serves the families of fallen SEALs and 9/11 responders. “A lot of the SEALS have done a number of tours all over the world. Most of the work they do is out of the public eye and they do not get the recognition or help they really need. Many of the vets have served for many years, and we feel it’s important to support them,” Marty says.

BARNES buildings also is a benefactor for the local Weymouth Junior Basketball League, and sponsors teams for youth football and Little League. Tony volunteers as a coach for both baseball and football teams. The company believes in giving back and donates to the Weymouth Food Pantry, the local D.A.R.E. program, St. Jude Children’s Research Hospital, the South Shore YMCA and the local Wounded Warrior Project.

Confidently Moving Forward

Marty Barnes has always looked forward and that has kept the business competitive and employees happy. Tony puts it into perspective. “There will always be a future for metal buildings. We are constantly evolving with the market and with new systems and using our design knowledge to find solutions for clients. That keeps them coming back to us and keeps us and our employees moving forward.”

Article Witten By: Marge O’Connor, a writer serving the international AEC community, is lauded for her storytelling skills by Who’s Who readers nationwide.

Article From: The Blue Book Building & Construction Network Expertise Drives Success

Print Edition: Who’s Who-Fall/Winter 2021 Boston, Eastern MA & New Hampshire (qgdigitalpublishing.com)

Testimonial

...In ranking performance of the several hundred contractors I’ve worked with Barnes Buildings is on the top of my list as number one....Henry A. Stout

President

Atlantic Properties

Featured Project